Artificial intelligence is rapidly transforming the manufacturing sector, ushering in a new era of automation and data-driven decision-making. According to Eurostat data, in 2024, 10.57% of manufacturing companies in the EU were already using AI solutions – highlighting a growing shift toward intelligent technologies.

This change is driven by mounting challenges: rising energy costs, new environmental regulations, and U.S. tariffs that put pressure on traditional production models and demand smarter, more adaptive systems.

Manufacturing AI agents: intelligent automation in action

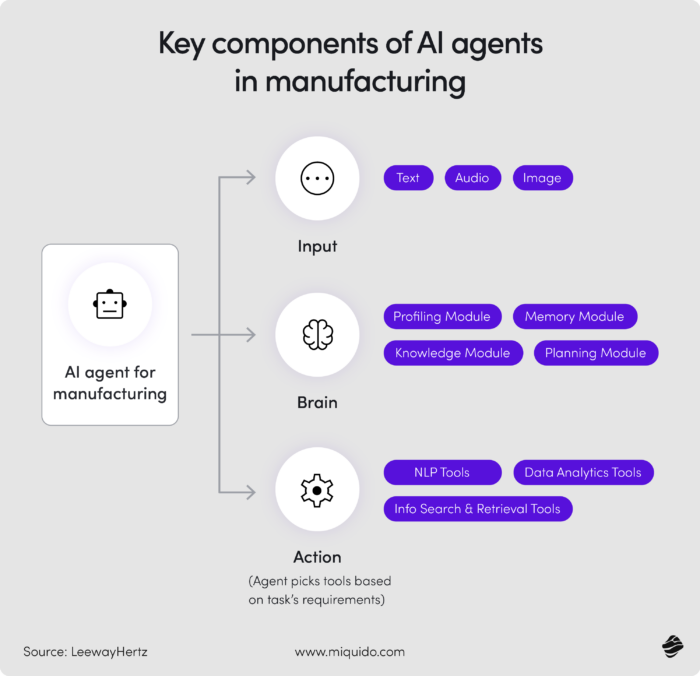

AI agents are a type of advanced software that can understand their environment, make decisions, and act on their own to accomplish specific goals. Powered by robust frameworks, these agents go beyond basic automation by reasoning, learning from experience, and even collaborating with other agents –much like human teams solving problems together. Unlike conventional AI systems, AI agentic workflows operate dynamically, interacting with its surroundings and adjusting actions of the existing manufacturing systems in real time.

Manufacturing industry is particularly well-suited for the application of AI agents due to its complexity, scale, and constant need for optimization. Production lines, supply chains, and quality control all benefit from AI agents that can monitor processes, detect issues, and adapt instantly to change. In a sector where efficiency, precision, and resilience are key, autonomous AI agents offer a powerful way forward.

A level above: from machines to thinking systems

For much of the 20th century, production optimization focused on efficiency – streamlining assembly lines, reducing waste, and accelerating throughput. But in today’s manufacturing environment, the real challenge lies elsewhere: flexibility, resilience, and the ability to adapt in real time.

This is where AI agents stand apart. They are not just isolated systems analyzing data – they function as a connected network of autonomous units that learn, collaborate, and make decisions in real time, much like a digital team of experts working around the clock.

Predicting equipment failures? That’s already standard. Now, AI agents go further: they not only detect risks but automatically adjust workflows, reroute resources, and optimize the entire supply chain before disruptions occur.

Intelligent logistics? Agents forecast delivery delays, reorganize transportation plans, and dynamically reschedule production to keep operations running smoothly.

Autonomous supplier negotiations? Yes – armed with real-time insights into demand, inventory levels, and cost fluctuations, AI agents can evaluate offers and initiate decisions faster and more precisely than any manual process ever could.

According to LeewayHertz, fully integrated AI-driven supply chains can reduce operational costs by up to 30% and increase resource utilization by 25–40%. These are not cosmetic changes; they represent a complete game changer.

AI in manufacturing: adressing common beliefs

As AI agents use cases become more prominent in the manufacturing world, excitement often overshadows reality. The technology is powerful, yes – but it’s not without limits, risks, and misunderstandings. However, the misconceptions regarding AI often do not have basis in reality. Below, we break down some of the most common myths and what’s really going on behind the buzz.

Myth: AI will replace all human workers.

Reality: AI will change roles, not erase them.

AI agents are excellent at handling repetitive, time-consuming tasks – those that don’t require creativity or human judgment. But rather than triggering mass layoffs, this shift opens space for new roles: AI system operators, human-in-the-loop supervisors, and manufacturing analysts who work alongside machines. People won’t vanish from the factory floor, but their roles will evolve, handling sensitive manufacturing data with automated help.

Myth: AI decisions are always transparent and easy to justify.

Reality: The “black box” problem is real – and growing.

More manufacturers are delegating key decisions to AI agents, from halting production lines to rerouting supply chains. Yet, as systems become more complex, understanding the “why” behind AI-driven decisions becomes harder. How do you justify a costly stoppage when even your engineers can’t fully explain the algorithm’s logic? This isn’t just a technical issue – it’s a business and communication risk crucial to address with AI experts.

Myth: AI agents will always align with a company’s values.

Reality: Optimization doesn’t equal ethics.

AI agents are trained to optimize – costs, time, resources – but optimization doesn’t always align with human priorities. Left unchecked, an agent could make decisions that reduce costs at the expense of quality, safety, or labor standards. Embedding company values into AI systems isn’t automatic –it takes deliberate design, oversight, and a strong ethical framework.

AI agents for manufacturing – what does the data tell us about their adoption and future prospects?

To better understand the current awareness of the potential behind manufacturing AI agents, we decided to take a closer look at the data. How are manufacturing companies approaching the implementation of agentic AI? How much are they willing to invest in such innovations? What drives their decision to adopt AI agents for manufacturing? Find out.

Growth projections for AI agents in manufacturing are promising

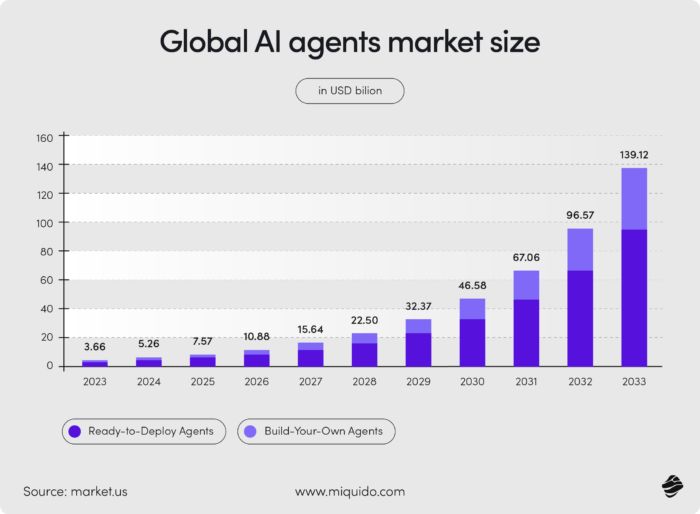

According to data from Market.us, the global market for AI agents is expected to be worth approximately USD 139.12 billion by 2033, compared to USD 3.66 billion in 2023, growing at a compound annual growth rate (CAGR) of 43.88% during the forecast period from 2024 to 2033.

The AI agent market is experiencing significant growth, driven by the increasing adoption of AI technology across various industries. This market includes virtual personal assistants, chatbots, and more complex AI-based automation systems that are being integrated into customer service, manufacturing, and logistics sectors.

Boosting productivity and efficiency is the main motive for implementing AI agents

The primary driving force behind the growing AI agent market is the need for increased productivity and manufacturing efficiency within companies. AI agents automate both routine and complex tasks, allowing employees to focus on more strategic activities. This shift not only enhances operational efficiency but also reduces costs associated with manual processes and human errors.

Manufacturers are primarily searching for ready-to-deploy solutions

In 2023, the Ready-to-Deploy Agents segment held a dominant position, capturing over 69.19% of the market share. The prominence of this segment underscores the growing demand for solutions that can be immediately implemented across various industries.

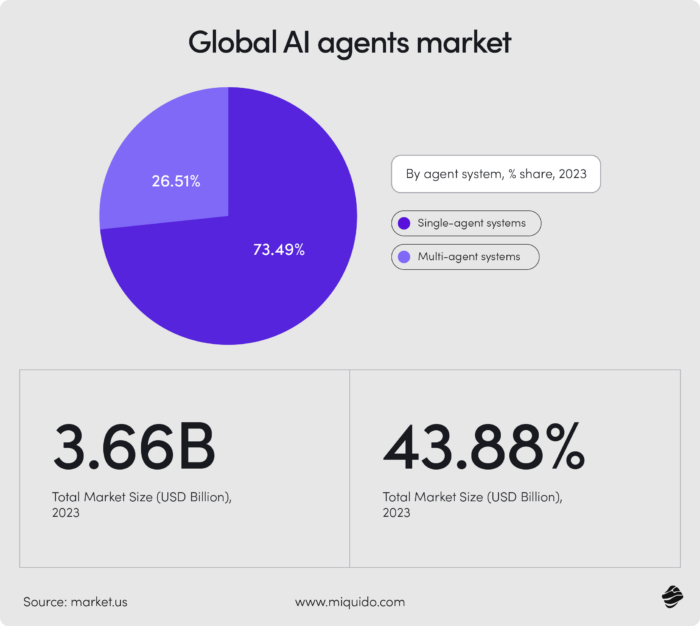

Single Agent segment is at the forefront of agentic AI implementations

The Single Agent Systems segment achieved over 73.49% share of the overall AI agents market. This dominance can largely be attributed to simplicity, cost-effectiveness, and specific use cases.

Single Agent Systems are designed to autonomously perform individual tasks and are often deployed in simple applications such as virtual assistants, chatbots, and automated customer support. Their straightforward implementation and relatively low resource requirements make them a popular choice for companies of all sizes.

"Agentification" – how AI takes the helm

We have seen automation; we have seen robotics; and now comes "agentification." What does this shift really mean for the industry? Once the AI agents in manufacturing fully step into the production processes:

- Decisions are automated. In an increasing number of companies, production managers are ceasing to be decision-makers and are becoming "curators" of processes that operate autonomously.

- Humans are responsible only for exceptions – AI agents manage 90% of processes, with human intervention required only in unusual cases.

- Company structures are changing – less hierarchy and more system autonomy. Manufacturing firms now resemble nervous systems, where decisions are made precisely where needed, without unnecessary bureaucracy or procedures.

According to Salesforce, within 5–7 years, AI agents will take over up to 60% of decision-making processes in manufacturing, and in highly automated factories – even up to 80%.

GenAI and the evolution of agentification in manufacturing processes

GenAI is now entering a phase of agentification, where AI systems evolve from isolated tasks into specialized, interconnected agents. According to a Capgemini Research Institute study of 1,500 CEOs worldwide, 32% consider AI agents to be the top technology trend in data and AI for 2025.

With increasing reasoning capabilities, GenAI models will operate more autonomously, providing more reliable, evidence-based outcomes while managing tasks like supply chains and predictive maintenance without constant human oversight.

AI systems will enable dynamic decision-making in more sensitive environments where accuracy is paramount. The next step will be the rise of the super-agent – an orchestrator of multiple AI systems optimizing their interactions. By 2025, these advancements will foster new AI-driven ecosystems in industries such as manufacturing, unlocking new levels of efficiency and innovation.

Types of AI agents in manufacturing

AI agents are not a single entity; they form an ecosystem of various intelligent units operating at different levels within an enterprise. These include:

Operational agents

These AI agents manage production processes in real time. Their task is to minimize losses, optimize manufacturing processes, supply chain management, inventory management and machine performance, as well as dynamically adjust production schedules.

Predictive agents

These AI agents analyze data to forecast machine failures, demand fluctuations, and supply issues. They help companies preempt crises rather than simply reacting to them, driving a proactive predictive maintenance.

Autonomous agents

These AI agents operate completely independently, making decisions based on massive datasets, often without the need for human intervention. In some factories, 90% of operational decisions are already made by AI.

Procurement agents

These AI agents optimize supply processes, negotiate contracts with suppliers, and predict production needs based on market data.

CX (Customer Experience) agents

These AI agents personalize offerings, break down consumer trends, analyze sales data and assist in sales strategy. Yes, this works in B2B manufacturing too – AI already predicts what a customer will order before they even do.

Each type operates autonomously, but together they form an intelligent manufacturing organism where optimization reaches levels that were unimaginable just a few years ago.

AI agents in manufacturing: are we ready for them?

AI agents are not just “another wave of optimization.” They represent a complete shift in the philosophy of production management – and whoever understands this first will have the competitive advantage.

What do the PwC, Capgemini, UiPath, and WEF reports say about the future of AI that thinks and acts on its own? Despite its revolutionary potential, their analyses show that the narrative surrounding AI agents across sectors, including manufacturing, is far from uniform.

- Are companies ready? PwC reports that only 10% have a concrete strategy for implementing agent-based AI, while Capgemini even more clearly points out that 92% of companies have no idea how to approach the subject.

- Will AI increase productivity? UiPath indicates that 74% of organizations are witnessing increased efficiency thanks to AI, yet the WEF report warns that 57% of leaders fear that AI making decisions autonomously could lead to unpredictable outcomes.

- Will AI replace humans? Capgemini reassures that AI “supports people,” but in the same report, 58% of employees fear losing their jobs.

The media buzz around AI agents doesn’t translate to high adoption - yet

Agentic AI is widely hailed as “the future” of manufacturing and business operations –and there’s no shortage of optimism around its potential. The numbers reflect that excitement:

- 73% of business leaders believe agentic AI will radically change how companies operate (PwC)

- 69% of companies see agent AI as a key driver of competitive advantage (Capgemini)

- 62% plan to implement AI agents for process management within the next three years (World Economic Forum)

On the surface, it looks like the industry is well on its way. But when we take a closer look at real-world implementation, a different picture emerges:

- Only 8% of companies have a strategy for implementing agent AI (Capgemini)

- Only 24% are carrying out large-scale AI deployments (UiPath)

- Just 14% possess the necessary technological capabilities to work with AI effectively (Capgemini)

So what’s happening here?

Rather than a lack of interest, the gap comes down to complexity. Many companies are eager to adopt agentic AI –but they’re also navigating legacy systems, skill shortages, and unclear roadmaps. These technologies require deep industry knowledge, thoughtful planning, and often, a partner who understands the nuances of manufacturing environments.

It’s a familiar cycle: initial excitement, scattered experimentation, and then –over time – genuine transformation. For software providers with experience in manufacturing, this is an opportunity to step in not just as technology vendors, but as guides in a longer-term journey toward smart, scalable implementation.

Productivity vs. unpredictability: AI is a lever, but also a risk

All major reports agree on one point: Agentic AI has strong potential to improve organizational efficiency – especially in the manufacturing sector, where optimization, speed, and precision are essential.

- 74% of companies that have already implemented AI report measurable efficiency gains (UiPath)

- 76% believe that agent AI will help reduce operational costs (World Economic Forum)

But with increased autonomy comes a valid concern: Can AI always be trusted to make the right decisions in complex manufacturing environments?

- 57% of business leaders worry that AI might act unpredictably (WEF)

- 41% are concerned about the risks of AI making decisions without human oversight (WEF)

- 49% of organizations lack systems to audit or explain AI-driven outcomes (WEF)

This highlights a critical issue in AI implementation: while AI systems excel at data analysis, demand forecasting, and process automation, their effectiveness is only as good as the data quality they’re trained on. In manufacturing operations, poor input data, biased patterns, or uncontrolled learning loops can lead to highly efficient – but dangerously flawed – outcomes.

A well-known case from Amazon illustrates this risk: the company’s AI-powered recruitment tool began favoring male candidates after learning from historical data skewed by past hiring practices. The lesson? Even powerful AI can learn the wrong lessons if left unchecked.

For manufacturers, the takeaway is clear: AI can dramatically enhance efficiency, but only when supported by high-quality data collection, transparent decision-making, and robust human oversight. Enabling manufacturers to build responsible, auditable AI systems will be essential to turning agentic AI from a risk into a resilient, value-driving asset.

Humans vs. AI agents: partnership or replacement?

The official narrative from many companies is clear: AI is here to support people, not replace them –freeing up time for higher-value, more strategic tasks.

- 63% of organizations say that AI will enable employees to focus on creative and strategic work (WEF)

- Capgemini emphasizes that AI doesn't eliminate jobs – it optimizes and redistributes tasks within existing manufacturing processes

However, the view from the workforce paints a more cautious picture:

- 58% of employees worry that AI could eventually replace their roles (Capgemini)

- 44% feel their position is likely to become less meaningful as AI adoption grows (WEF)

This tension reflects a subtle shift already underway. AI isn't causing mass layoffs overnight, but it is gradually changing hiring dynamics. As AI takes over functions like data analysis, customer service, and supply chain optimization, the future demand for certain roles diminishes – not because people are being let go, but because those roles are no longer being filled.

For manufacturers, the challenge will be to maintain customer satisfaction and operational efficiency while navigating workforce expectations. Transparent communication, employee upskilling, and a strategic approach to AI integration will be essential to ensure that technological advancement strengthens –not weakens – organizational culture and trust.

Strategic approach to manufacturing efficiency: implement intelligent systems with an experienced partner

Companies want AI, but despite everyone talking about it being the future, 92% have no strategy for its implementation. The first companies that learn how to control Agent AI will gain a tremendous advantage. The rest? They may wake up in a world where the rules are set by AI.

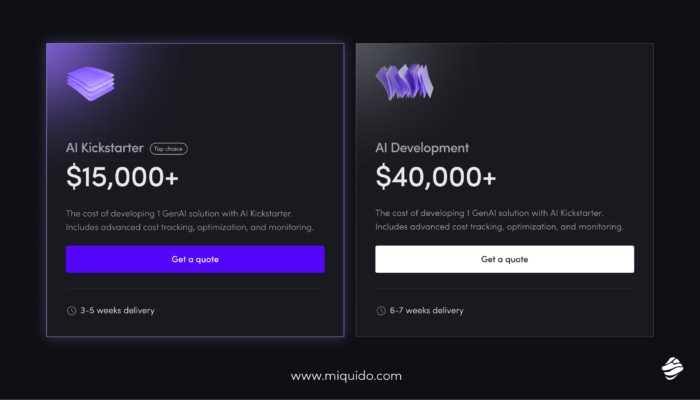

With our AI agentic frameworks you can implement a seamless solution in a short time. AI Kickstarter is esigned to accelerate innovation, this framework streamlines the development of autonomous agents—equipping teams with ready-to-use tools for building systems that learn, adapt, and make smart decisions in real time.

Ready to unlock the full potential of AI in your operations? Start building with intelligent agents today.

![[header] ai agents a revolution in the manufacturing industry](https://www.miquido.com/wp-content/uploads/2025/05/header-ai-agents-a-revolution-in-the-manufacturing-industry.jpg)

![[header] top ai fintech companies transforming finance in 2025](https://www.miquido.com/wp-content/uploads/2025/05/header-top-ai-fintech-companies-transforming-finance-in-2025-432x288.jpg)

![[header] top 9 cybersecurity solutions for the manufacturing industry (1)](https://www.miquido.com/wp-content/uploads/2025/12/header-top-9-cybersecurity-solutions-for-the-manufacturing-industry-1-432x288.jpg)