Manufacturers in 2026 are operating under intense pressure. Trump’s tariffs are disrupting supply chains, demand in construction and related industries is softening due to the global economic slowdown, and energy prices remain stubbornly high. At the same time, businesses are expected to meet costly sustainability standards. In this environment, generative AI (GenAI) is becoming a strategic tool for manufacturers that need to adapt quickly, cut costs, and maintain competitiveness.

In this article, we explore the potential of specific generative AI use cases in manufacturing. You will learn about the benefits of each one, the challenges you may face, and how to overcome them. Drawing on our experience from multiple deployments of Gen AI, we share insights you can put into practice today.

How is generative AI revolutionizing modern manufacturing?

To understand the role of generative AI, it helps to start with Industry 4.0. But what is Industry 4.0? In simple terms, it is the fourth industrial revolution—an era of fully connected, automated, and data-driven factories. It integrates robotics, IoT, and cloud computing, enabling machines and systems to share information and optimize themselves with minimal human intervention.

AI and GenAI are both core components of Industry 4.0, but they work in different ways. AI predicts and analyzes, while GenAI can also design, generate, and reimagine processes. Think of it this way: AI might detect defects in a batch of products before they leave the plant, while GenAI would go a step further by redesigning the workflow to prevent defects altogether.

GenAI is already transforming manufacturing across four key areas:

- Sales and customer service – multilingual support, intelligent product configuration, and automated order handling

- Quality control – enriched data, improved anomaly detection, and automated inspections

- Workforce management – personalized training and instant updates to work instructions

- Compliance – continuous monitoring of regulatory changes and automated ESG reporting

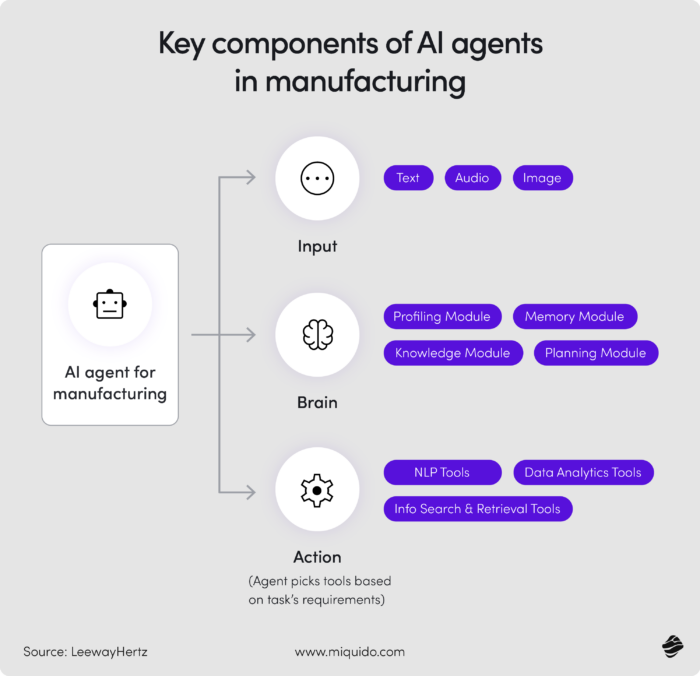

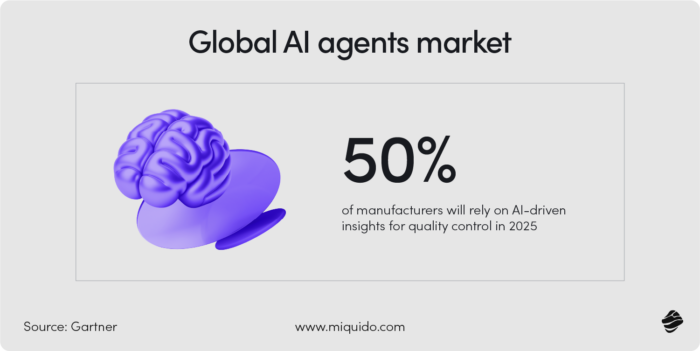

AI agents in manufacturing operations: Your goal-oriented assistants

AI agents are the next evolution of automation. These advanced software systems can observe their environment, make decisions, and act independently to achieve defined goals. They do more than just follow instructions. They learn, reason, and even collaborate with other agents—just like human teams solving complex problems together. Unlike conventional AI, they adjust actions in real time based on changing factory conditions.

- In sales and customer service, AI agents act like tireless account managers. They answer customer queries in multiple languages, track inventory in real time, and generate precise delivery dates—often before a human could even draft a response.

- In quality control, these agents are the ultimate watchdogs. They scan streams of machine data 24/7, fine-tune inspection tools on the fly, support predictive maintenance, and trigger corrective actions the moment production drifts off-spec.

- For workforce management, they become dynamic planners. They forecast staffing needs, build shift schedules that balance workloads, and instantly deliver training modules to employees when new procedures roll out.

- And in compliance, AI agents quietly act as your internal auditors. They keep up with the latest regulatory changes and compile ESG reports automatically, ready for inspection at any time

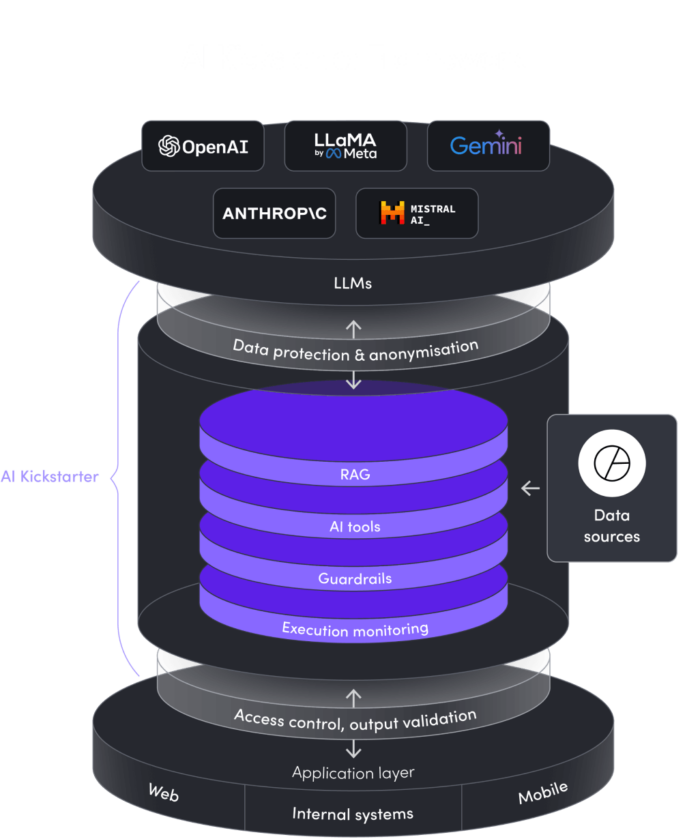

Let's move to specific Generative AI business use cases that can be applied in production processes relatively easily with significant ROI. With our AI Kickstarter framework, you can apply solutions below at the fraction of costs of traditional development.

How to reduce customer service costs and eliminate order processing errors with Generative AI?

Manufacturers are under pressure to keep costs under control while customer expectations are rising. In today’s market, even well-established companies struggle to stay profitable, and small errors can have a big financial impact.

This is why solutions such as customer service automation and error-free order processing are gaining momentum, especially in niche sectors like automation in joinery where speed and accuracy are critical to retaining customers.

The good news? These improvements not only reduce costs but also build long-term loyalty, which matters most in just-in-time operations where delayed responses can quickly lead to churn in both B2B and B2C relationships.

Multilingual customer support powered by company knowledge bases

One of the fastest ways to improve customer service and cut costs is to deploy generative AI systems capable of resolving customer queries at scale. Using advanced generative AI models, these tools tap into vast company knowledge bases, technical documentation, and product catalogs through RAG architecture. They identify patterns in correspondence history, search CRM data for context, and then generate personalized responses in dozens of languages simultaneously.

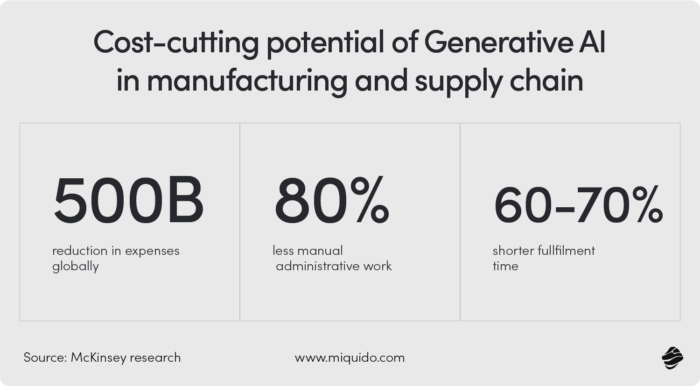

This level of customer service automation has a real financial impact. AI chatbots handle up to 80% of routine inquiries, freeing teams to focus on complex cases. The result is a 70% reduction in cost-per-chat on average and faster response times that build customer trust. In a competitive manufacturing sector, shortening fulfillment time by 60–70% can be a game changer.

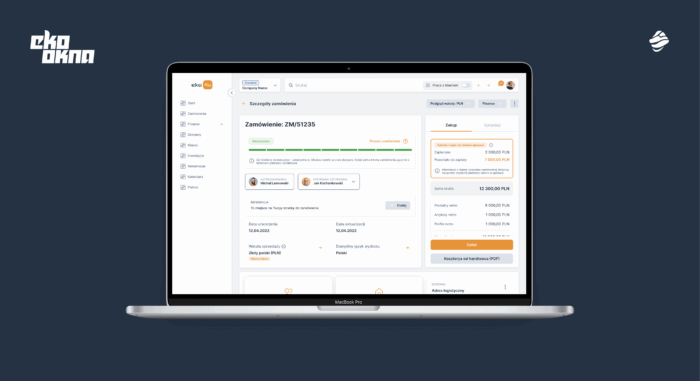

Automated order processing

Every manufacturer knows how a single mistake in an order can spiral into wasted materials, costly delays, and unhappy customers. AI and machine learning now make it possible to digitize and automate the entire order management workflow. OCR systems recognize documents in any format such as scans, photos, or PDFs, while intelligent configurators analyze technological rules, check component availability, and validate data before it hits your ERP system.

This level of integration with inventory management and CRM eliminates manual errors and speeds up supply chain optimization. Orders are automatically transformed into standardized formats and pushed into APS systems, with error detection modules flagging any irregularities. The outcome is clear: fewer mistakes, faster processing, and greater customer satisfaction, all while reducing operational costs in the manufacturing sector.

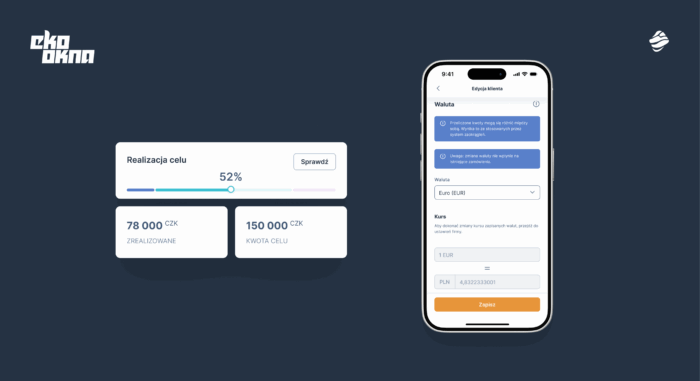

Intelligent billing and payment matching

Payments are another area where automation pays off. Traditional reconciliation processes rely heavily on manual data entry, but generative artificial intelligence can change that completely. AI systems analyze incomplete or inconsistent transfer data, automatically match payments to the correct orders, and integrate seamlessly with ERP and CRM systems to keep records fully synchronized.

Because generative AI takes advantage of historical data, it can even flag unusual transactions or potential fraud. This means finance teams no longer waste time hunting for missing references, and invoices are closed faster. By reducing the lag between payment and confirmation, companies strengthen cash flow and minimize costly disputes.

How to improve production quality and reduce material waste with Gen AI?

Material waste costs more than ever in today’s manufacturing environment. Companies pay not only for lost materials but also for the CO₂ emissions associated with excess production. Add strict quality requirements and higher customer expectations, and it becomes clear why ai driven quality control is essential.

Automating these areas does not just minimize environmental impact. Generative AI for production planning, quality control and optimization saves money, reduces scrap, and helps manufacturers boost productivity while ensuring improved quality control standards are met.

Training data enhancement for computer vision systems

High-performing computer vision models rely on vast amounts of labeled training data, which can be expensive and time-consuming to gather. Generative AI in manufacturing now makes it possible to bridge these data gaps with synthetic data. Manufacturers can generate defect images for specific products, create rare error scenarios, and continually refine models using real production data without halting production lines.

The ROI is significant. Enhanced datasets can reduce product testing costs, shorten quality control cycles, and cut logistics expenses. Merck is a compelling example. By integrating AWS services with cutting-edge AI in manufacturing, they use GANs and Variational Autoencoders to simulate complex defects. This has transformed their quality control processes, reducing deviations, improving safety, and saving millions annually.

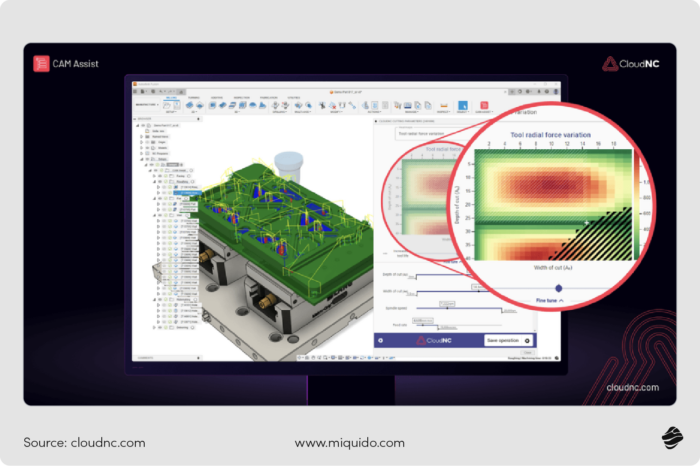

Cutting optimization and waste minimization

Material utilization is one of the most powerful cost levers in production. Using optimization algorithms, manufacturers can analyze order patterns, forecast demand, and generate automatic CNC instructions that maximize material yield.

By integrating AI with warehouse management systems, facilities cut waste by up to 10% and often achieve ROI in the first month. Less waste translates directly to lower maintenance costs, faster production cycles, and improved bottom-line performance.

Predictive quality control in serial production

Traditional quality control detects defects after they occur. Predictive systems, however, use sensor data and digital twin technology to anticipate issues before they happen. These solutions analyze process parameters in real time, automatically adjust machine settings, and alert operators when critical production pumps or other assets deviate from normal operation.

The benefits are measurable. AI for quality control means fewer defective products, warranty cost savings, and improved uptime. Predictive quality control can cut defects by 25–40% while making production lines more resilient.

How to efficiently train teams and automate procedure updates with GenAI?

Finding qualified workers remains one of the biggest challenges for manufacturing companies. In Europe, surveys show that 75% of employers across 21 countries reported difficulty finding workers with the right skills in 2023, up sharply from 42% in 2018. These shortages are creating serious bottlenecks across supply chain management. Especially the relatively new niches, like automotive EV, are struggling to full their open technical roles, and are investing in upskilling initiatives in both the U.S. and Europe.

Compounding this issue is high employee turnover, which is especially common in sectors like food processing or packaging. In many cases, employers invest in lengthy onboarding programs only to see employees leave within months. Traditional training simply isn't designed for such volatility. By switching to AI in manufacturing, companies can optimize processes and deliver role-specific training for a fraction of the cost—and in a fraction of the time.

Language barriers add another layer of complexity. In countries like Poland, where the local language is notoriously difficult, the manufacturing sector is increasingly relying on workers from Eastern Asia. Here, generative AI systems equipped with automatic translation and contextual training tools can help fill the gap, enabling efficient, multilingual knowledge transfer from day one.

In this context, training is no longer just about skill-building—it’s a strategic advantage. With the help of data analysis and traditional AI evolving into more adaptive generative models, manufacturers are not only scaling training faster but also tailoring it to the exact needs of each role and employee.

Personalized training materials for every position

Standardized onboarding doesn't work when every production role has different requirements, learning curves, and safety risks. With the rise of generative AI in manufacturing, it’s now possible to automatically generate role-specific training materials adapted to a person’s skill level, job function, and learning pace. Using interactive simulations and scenario-based content, new employees can train in virtual environments that mimic real factory conditions.

AI in manufacturing has unlocked smarter onboarding by integrating data analysis with adaptive learning. Systems can now track employee progress, adjust learning paths in real time, and provide content in multiple languages through automatic translation. The benefits are clear: onboarding time drops by 53%, knowledge retention goes up by 82%, and even high-turnover positions receive consistent, high-quality training.

Automatic procedure updates and compliance

In today’s dynamic regulatory environment, staying compliant is no longer a once-a-year task. For global exporters, each country has its own industrial and safety standards, which often change and even contradict each other. Manual tracking is too slow and too costly. AI for manufacturing compliance offers a smarter way to keep documentation, instructions, and certifications up to date automatically. GenAI systems continuously monitor changes in ISO norms, EU directives, and national regulations using advanced production monitoring software.

GenAI systems continuously monitor changes in ISO norms, EU directives, and national regulations. Once a new guideline is identified, they generate specific updates for each production area and notify relevant employees about required training.

In sectors like pharmaceuticals, for example, when the FDA updates GMP protocols, the system can instantly generate new instructions for cleanroom procedures and auto-schedule refresher training for line operators. This ensures that teams remain compliant and audit-ready at all times without administrative delays.

How can you ensure compliance and automate ESG reporting?

In 2026, the EU’s Corporate Sustainability Reporting Directive (CSRD) will apply to the majority of medium and large manufacturing companies, covering both public and private entities. Similar regulations are expanding in North America, particularly in California and Canada, for companies exceeding specific revenue or operational thresholds. These new obligations require detailed reports covering emissions, working conditions, and sourcing of raw materials—and that includes every link in the supply chain.

Generating these reports is more than a checkbox exercise. It involves pulling together vast amounts of siloed data from logistics, procurement, production, and HR systems. Reports must be not only compliant with international standards but also readable, actionable, and supported by traceable audit logs. Manually creating such reports is time-consuming, expensive, and prone to error. That’s where AI tools come in.

Automated ESG report generation from supply chain

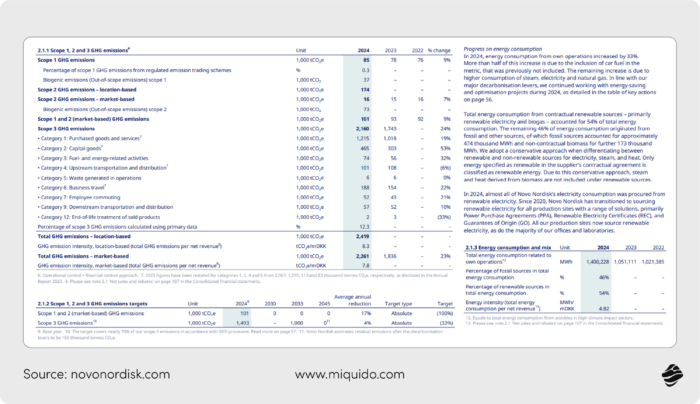

Sustainability reporting is no longer optional, and it’s no longer limited to emissions from your own operations. Most regulations now require full emissions tracking across the supply chain, split into categories such as Scope 1, 2, and 3. For most manufacturers, this means aggregating data from multiple external and internal systems, calculating impact metrics, and producing reports aligned with frameworks like GRI or TCFD.

Generative AI systems automate this end-to-end. They pull structured and unstructured data from suppliers, logistics providers, and production databases. Then, they automatically calculate carbon footprints per product or SKU, generate reports in formats required by different regulatory bodies, and even highlight areas where environmental performance can be improved.

The impact is substantial. Companies save time, avoid regulatory penalties, and gain insights that help them meet their sustainability goals. Instead of spending weeks compiling data manually, businesses use GenAI to generate reports in hours and focus efforts on process optimization and demand forecasting.

Global and regional regulation monitoring

For global manufacturers, regulatory complexity increases with every new market. Keeping track of different rules and understanding how they impact production, packaging, labeling, and transport can quickly overwhelm compliance teams. That’s why many firms are now turning to AI for manufacturing compliance to monitor legal changes in real time.

GenAI systems track regulatory updates across all relevant jurisdictions, from carbon caps in Europe to labeling requirements in Southeast Asia. When a new rule is identified, the system performs data analysis to assess its potential impact and generates clear guidelines for implementation. Local teams receive alerts on compliance deadlines and are provided with tailored instructions aligned to their operational reality.

By mapping regulatory risks and automating the creation of action plans, manufacturers not only reduce penalties but also shorten preparation cycles dramatically. According to industry data, compliance automation cuts reporting time from weeks to hours and reduces regulatory risk by up to 85%.

This supports the broader expansion of artificial intelligence in manufacturing, a market valued at USD 4.2 billion in 2024 and growing at a CAGR of over 31% through 2034.

Benefit from Generative ai use cases in manufacturing

The question isn't whether to implement GenAI in manufacturing, but how quickly you can start. A smooth pathway to Generative AI adoption? We recommend starting with pilot projects in high-impact areas like customer service or quality control, and then scale successful implementations across your organization. Chat to our experts to explore potential benefits!

![[header] top 10 generative ai use cases in manufacturing](https://www.miquido.com/wp-content/uploads/2025/07/header-top-10-generative-ai-use-cases-in-manufacturing.jpg)

![[header] top ai fintech companies transforming finance in 2025](https://www.miquido.com/wp-content/uploads/2025/05/header-top-ai-fintech-companies-transforming-finance-in-2025-432x288.jpg)

![[header] top 9 cybersecurity solutions for the manufacturing industry (1)](https://www.miquido.com/wp-content/uploads/2025/12/header-top-9-cybersecurity-solutions-for-the-manufacturing-industry-1-432x288.jpg)