While discussions around Industry 4.0 often focus on robotics, IoT sensors, and artificial intelligence, in reality, the most impactful changes are happening outside the factory floor. Digital transformation enhances customer engagement and customer experiences through omnichannel integration, allowing manufacturers to interact with customers across multiple platforms and deliver more personalized, seamless service.

What truly builds a competitive edge in manufacturing happens at the points of contact: where the customer interacts with the system, where an order becomes a production task, and where data becomes actionable insight. Connected devices play a crucial role in enabling data collection and communication between systems, driving automation and intelligent manufacturing processes.

Data analytics and big data analytics are now used to provide actionable insights, drive innovation, and optimize supply chain management. Machine learning and machine learning algorithms help identify patterns in manufacturing data to optimize operations and predict future trends. Additionally, utilizing data analytics allows manufacturers to personalize customer experiences and improve support, leading to greater satisfaction and loyalty.

Advanced manufacturing technologies and technological advancements are transforming the industry by enabling smarter, more connected, and efficient operations. The integration of cyber physical systems and smart factories, along with the use of virtual representations and digital models, allows for real-time simulation, monitoring, and optimization of physical assets and processes.

These technologies lead to enhanced product quality and improved product quality, while reducing human error and improving efficiency. The industrial environment itself is being transformed through the adoption of these innovations, creating new opportunities and revolutionizing manufacturing operations.

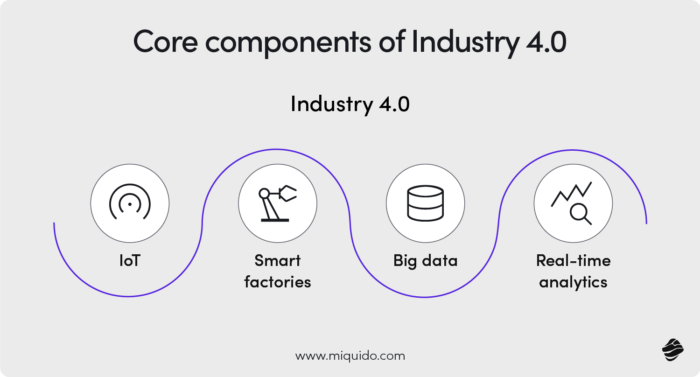

Key technologies driving Industry 4.0

The fourth industrial revolution is powered by a suite of advanced technologies that are transforming the manufacturing industry from the inside out. Artificial intelligence (AI) is at the forefront, enabling manufacturers to harness data analysis for smarter, faster decision-making. By utilizing AI-driven predictive maintenance, companies can anticipate equipment failures before they happen, minimizing downtime and reducing maintenance costs. This proactive approach allows manufacturers to optimize production schedules and keep operations running smoothly.

Real time data sharing, enabled by the Internet of Things (IoT), connects machines, devices, and systems across the factory floor and beyond. This interconnectedness provides valuable insights into every stage of the production process, from raw materials to finished goods. With access to real time data, manufacturers can identify inefficiencies, improve quality control, and make data-driven decisions that enhance operational efficiency.

Data analysis is another cornerstone of Industry 4.0, turning vast amounts of information into actionable intelligence. By analyzing production processes and equipment performance, manufacturers can uncover patterns, optimize operations, and reduce costs. Together, these technologies are revolutionizing manufacturing, making it possible to respond quickly to market changes and deliver higher quality products with greater efficiency.

What does omnichannel mean in manufacturing?

In e-commerce, “omnichannel” means a seamless experience across sales channels. In manufacturing, it means strategic integration of data and processes, spanning:

- B2B sales,

- logistics,

- service and after-sales support,

- finance,

- production.

Omnichannel strategies also enable chain optimization and inventory management by integrating real-time data across all operations, supporting better decision-making and responsiveness.

A well-implemented omnichannel approach in industrial companies not only improves the customer experience, but also ensures data consistency, lower costs, and greater operational predictability. Through digital transformation and omnichannel integration, companies achieve supply chain optimization by leveraging real-time data, analytics, and automation to enhance efficiency and collaboration.

3 key areas of operational advantage in manufacturing

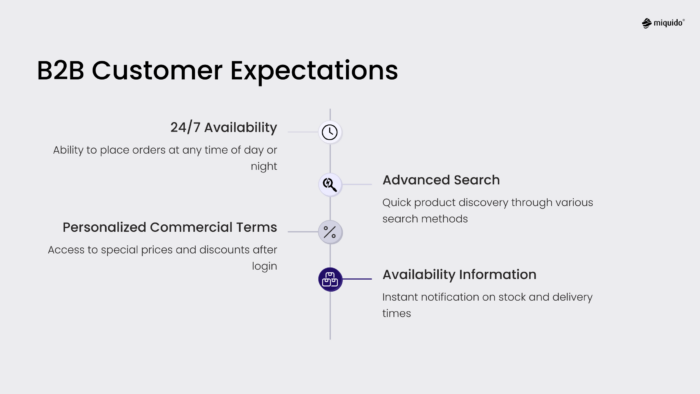

1. B2B Customer Service

Today’s industrial customer expects full self-service and 24/7 access — without needing to contact a sales rep.

Examples of implemented solutions:

- A web/mobile platform for dealers with registration, login, and access to order data – increasing transparency and reducing call center load,

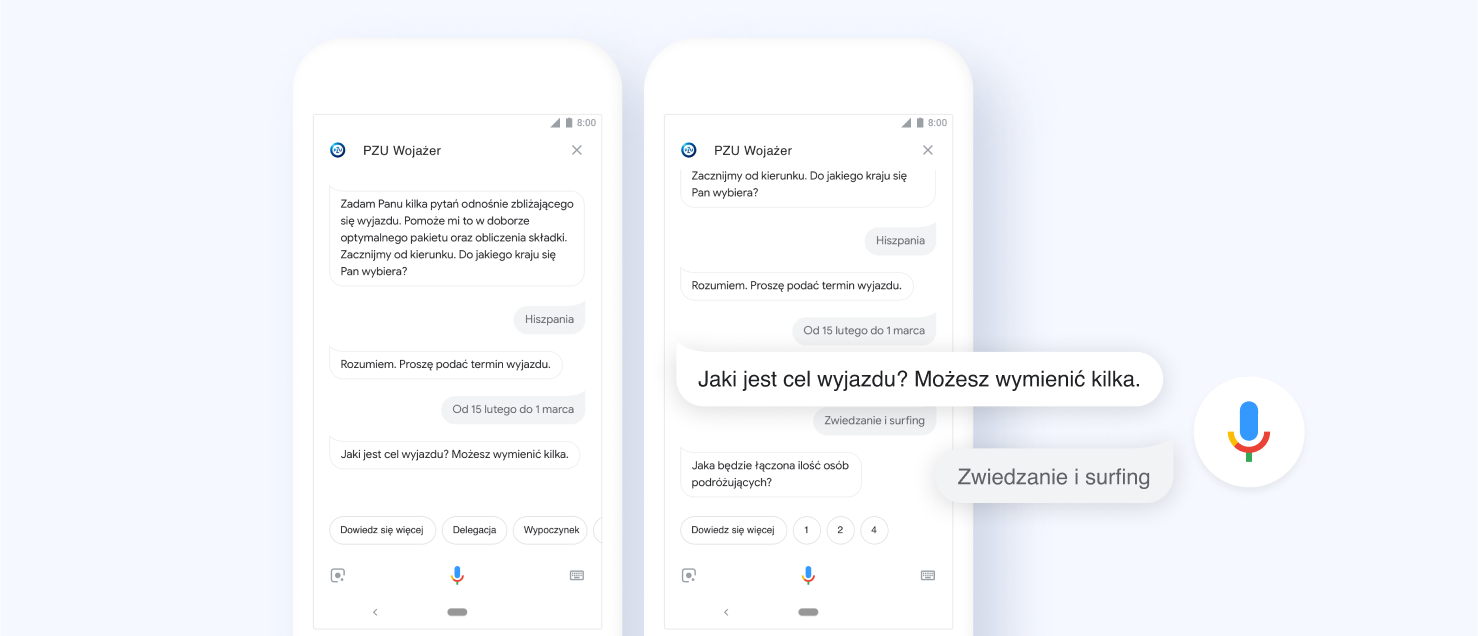

- A multilingual AI chatbot connected to the factory’s knowledge base – answering customer questions from various markets,

- A digital complaints process – customers submit photos and data through the system; the issue is automatically assessed and resolved,

- Delivery and rack collection notifications – mobile apps informing about fulfillment stages and pickup needs.

2. Logistics, deliveries & predictive maintenance

Omnichannel logistics requires continuous information exchange and integration with various transport and warehouse systems.

Implemented tools include:

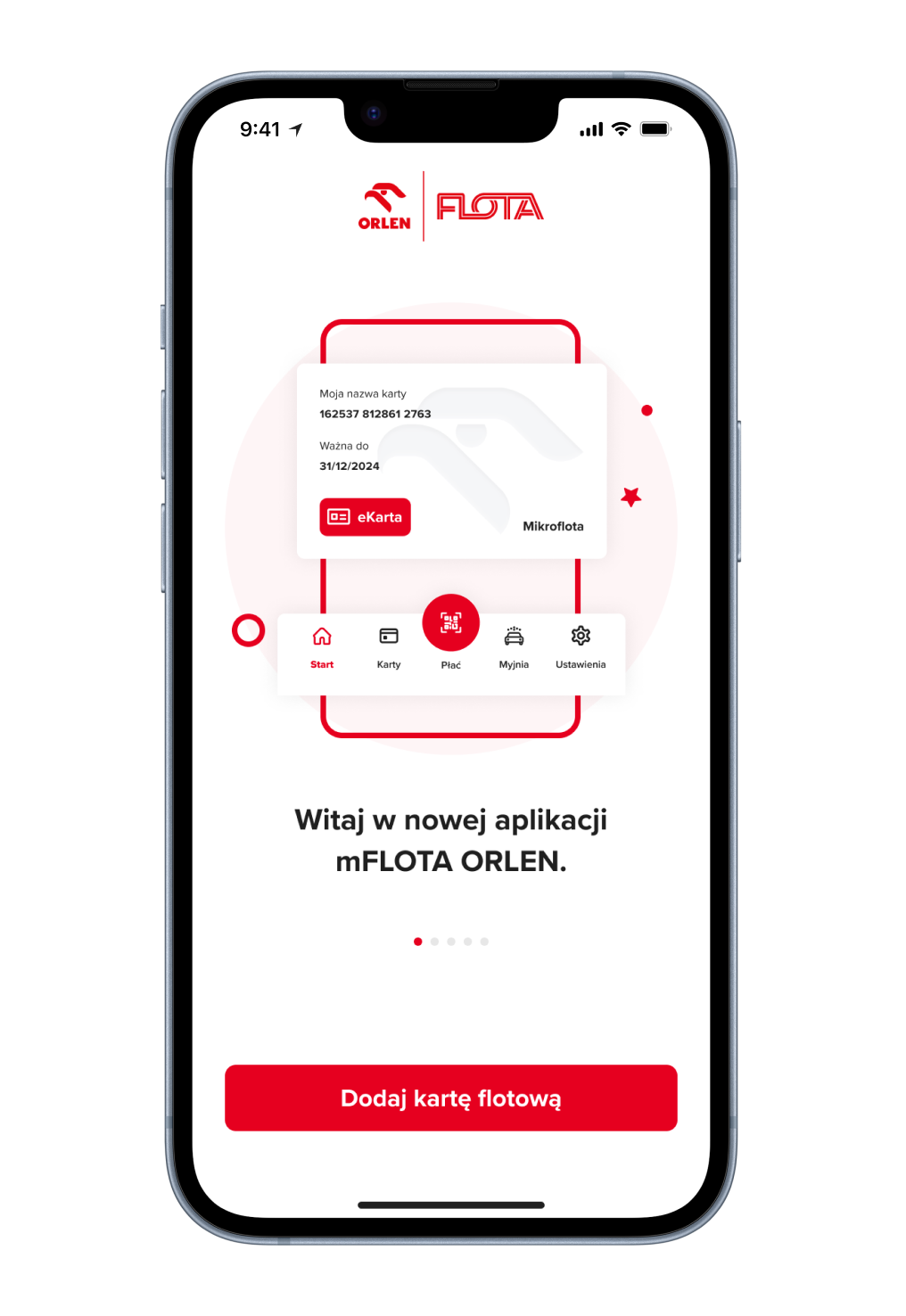

- Mobile apps for drivers – enabling confirmation of deliveries and returns (e.g., racks or reusable packaging),

- Real-time delivery notifications – eliminating the need for manual communication between driver and office,

- Photo documentation of loading and unloading processes – linked directly to the order,

- A data bus (data layer) – ensuring consistent, real-time information flow between logistics, production, and sales.

3. Payments, financial integration & data analysis

Omnichannel also means full automation of financial operations, directly improving cash flow and minimizing errors.

Practical implementations:

- ERP integration with payment gateways – speeding up payment confirmation and production release,

- mPOS (mobile point of sale) for drivers – enabling on-the-spot payment collection,

- AI-based payment identification – automatically linking payments to orders based on learned patterns,

- Centralized payment documentation – automated confirmation, invoicing, and reconciliation processes.

Data privacy and security in the age of digital manufacturing

As digital transformation accelerates across the manufacturing industry, data privacy and security have become critical priorities. The adoption of Industry 4.0 technologies means manufacturers are collecting and analyzing more data than ever before—ranging from production processes and supply chain operations to sensitive customer interactions. Protecting this wealth of information is essential for maintaining a competitive edge and ensuring business continuity.

To safeguard data, manufacturers must implement robust cybersecurity measures, including encryption, secure authentication, and regular system audits. Compliance with regulations such as the General Data Protection Regulation (GDPR) is also vital, especially when handling data that crosses international borders. By prioritizing data privacy and security, manufacturers not only protect their own operations and supply chain, but also build trust with customers and partners throughout the supply chain.

In an era where digital solutions are integral to every aspect of production, a strong security posture is no longer optional—it’s a fundamental requirement for success in the modern manufacturing industry.

Workforce skills gap: Preparing teams for manufacturing 4.0

The rapid adoption of Industry 4.0 technologies is reshaping the skills required in the manufacturing sector. As digital transformation introduces advanced tools like AI, predictive maintenance, and data analysis, manufacturers face a growing workforce skills gap. To remain competitive, companies must invest in upskilling and reskilling their teams, ensuring employees are equipped to thrive in a digital-first environment.

Training programs focused on data analysis, predictive maintenance, and cybersecurity are essential for building a workforce capable of leveraging new technologies. Encouraging a culture of continuous learning and innovation helps teams stay ahead of emerging trends and adapt to evolving production processes. By preparing employees for the demands of Manufacturing 4.0, companies can optimize operations, improve quality control, and drive ongoing success in a rapidly changing industry.

What’s already working? Examples of omnichannel in manufacturing

- OCR + AI recognition of order PDFs – automatic processing into ERP/MES without manual input

- Multilingual B2B chatbots – supporting global dealer networks 24/7

- AI-powered complaint management – based on images, order data, and integrated quality systems

- Delivery and rack notifications – mobile alerts for logistics teams and drivers

- mPOS and AI payment recognition – instant verification and linking of payments to production

- Data bus + process automation (e.g., n8n) – automatic status updates, report generation, and low-code system communication

4. Key questions to ask your IT or operations team

- Can the customer check their order status without contacting us?

- Do we know which orders are already paid vs. just issued?

- Can complaints be submitted without calls or emails?

- Are production systems integrated with sales and finance platforms?

If the answer to any of these is "no" — that’s exactly where to begin.

You may not need million-euro investments, just smart integration of existing tools.

The future of manufacturing: what’s next for omnichannel and digital integration?

Looking ahead, the future of manufacturing will be defined by even deeper integration of omnichannel strategies and digital technologies. As advanced analytics, artificial intelligence, and interconnected systems become standard, manufacturers will gain unprecedented visibility and control over their supply chains and production lines. Real time data sharing and predictive analytics will enable companies to optimize supply chains, respond instantly to shifts in customer demand, and deliver a truly unified customer experience.

Emerging technologies such as digital twins, advanced robotics, and cloud computing will further revolutionize manufacturing processes, enabling intelligent factories that can self-optimize and adapt to changing market trends. Supply chain transparency and data-driven decision making will become the norm, driving significant benefits in operational efficiency, cost savings, and customer satisfaction.

To stay ahead, manufacturers must continue to embrace digital transformation, invest in workforce development, and prioritize data privacy and security. By doing so, they will not only remain competitive but also lead the way in shaping the next era of the manufacturing industry.

Conclusion: Integrate before you invest

Omnichannel in manufacturing is no longer optional.

It’s essential for companies that want to scale without chaos.

With smart data integration, process automation, and information transparency, you can:

- increase visibility and control,

- reduce operational costs,

- speed up fulfillment and payment,

- and improve the B2B customer experience.

Not every transformation requires new technology - sometimes all it takes is a new perspective on what you already have.

![[header] how omnichannel and digital integration are reshaping manufacturing](https://www.miquido.com/wp-content/uploads/2025/06/header-how-omnichannel-and-digital-integration-are-reshaping-manufacturing_.jpg)

![[header] top 9 cybersecurity solutions for the manufacturing industry (1)](https://www.miquido.com/wp-content/uploads/2025/12/header-top-9-cybersecurity-solutions-for-the-manufacturing-industry-1-432x288.jpg)

![[header] b2b ecommerce for manufacturing – 21 feature ideas for cutting costs and multiplying sales](https://www.miquido.com/wp-content/uploads/2025/09/header-b2b-ecommerce-for-manufacturing-–-21-feature-ideas-for-cutting-costs-and-multiplying-sales-432x288.jpg)

![[header] top 10 generative ai use cases in manufacturing](https://www.miquido.com/wp-content/uploads/2025/07/header-top-10-generative-ai-use-cases-in-manufacturing-432x288.jpg)