In today’s interconnected world, predictive capabilities have become more crucial than ever – they now form the backbone of modern manufacturing. Like a skilled navigator reading storm clouds on the horizon, manufacturers must anticipate market turbulence before it strikes. But why has this foresight become so essential in 2025’s manufacturing landscape?

The perfect storm: Key market forces reshaping manufacturing

As the global market landscape makes is increasingly harder to maintain competitiveness, effective predictive analytics in manufacturing is more needed that ever. Here’s what drives demand for advanced AI-based systems.

Geographic production dependencies

The European Union’s highly sectorized production across member countries requires sophisticated demand and supply forecasting mechanisms. Without these, the delicate harmony of cross-border supply chains could quickly devolve into market chaos. Each country’s specialized manufacturing sectors must synchronize perfectly – a miscalculation in German automotive parts could ripple through Italian assembly plants within days.

Climate-driven supply chain disruptions

Climate change continues to disrupt supply chains and transportation routes in unprecedented ways. Extreme weather events now regularly paralyze logistics networks, making the availability of products and raw materials far more volatile than just a few decades ago. Droughts and floods increasingly alternate in critical regions for food production, creating a cascade effect that reaches far beyond agriculture into industrial manufacturing processes.

Financial volatility and market uncertainty

This instability naturally impacts costs across the board. Energy and raw material prices fluctuate dramatically, negatively affecting manufacturing companies’ financial stability. Additionally, tariffs imposed by the United States – a key export destination for many countries – make it increasingly difficult to predict the profitability of existing strategies. Can manufacturers afford to maintain their current approaches when market conditions shift so rapidly?

Manufacturing predictive analytics today: From optimization to survival

Cost prediction and dynamic adjustment of procurement and production plans based on these forecasts is no longer about optimization – it’s about market survival. According to research by Deloitte, manufacturers implementing predictive maintenance systems report a 30-50% reduction in machine downtime and a 10-40% decrease in maintenance costs, demonstrating the tangible impact of predictive approaches on operational efficiency.

The numbers speak volumes about this growing trend: the global predictive analytics market size is projected to grow from $22.22 billion in 2025 to $91.92 billion by 2032, at a CAGR of 22.5%, reflecting the urgent need for predictive capabilities across industries.

The manufacturing response: Preparation over reaction

Predictive analytics doesn’t solve these problems at their source, but it enables manufacturers to prepare and respond proactively – avoiding downtime and cost increases before they materialize. Its applications in manufacturing are remarkably broad, encompassing:

- Predictive maintenance to prevent equipment failures

- Demand forecasting to optimize production and inventory levels

- Quality control to identify defects before they occur

- Supply chain optimization to anticipate and mitigate disruptions

- Energy management to reduce consumption during peak pricing periods

In this article, we examine these applications more closely, explaining through concrete case studies how they can transform plant operations and provide the competitive edge that modern manufacturing demands.

Predictive analytics use cases in manufacturing industry

Predictive analytics in manufacturing helps optimize processes across the entire manufacturing plant, from inventory management to energy usage. A crucial step towards digital transformation, it makes a foundation for Industry 4.0, driving scalable growth and long term sustainability.

The ultimate goal? Maximum efficiency. And as the research by Delloite shows, it can indeed bring measurable results in short time.

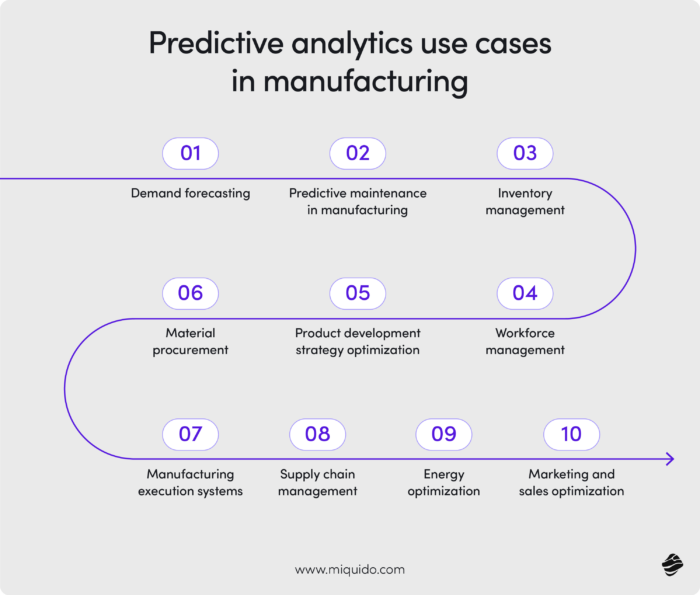

To understand the role of predictive analytics in manufacturing plant operations, it’s worth beginning by outlining its key areas of application. As shown in the example below, its utilization extends from back-office operations to the factory floor and warehouses, connecting production process planning, execution, and subsequent steps related to distribution.

Maximizing the potential of predictive analytics requires seamless collection and integration of data from various sources. Manufacturing organizations rely on multiple data streams:

- IoT sensors for real-time equipment monitoring

- Manufacturing execution systems (MES) for production tracking

- Enterprise resource planning (ERP) systems for business operations

- Supervisory control and data acquisition (SCADA) systems for process control

- Quality management systems (QMS) for product standards

- Computerized maintenance management systems (CMMS) for asset upkeep

- Warehouse management systems (WMS) for inventory control

- Production line sensors for operational data

However, internal data alone rarely suffices. Most successful predictive analytics implementations also incorporate:

- Partner and distributor system data

- Customer demand patterns and feedback

- Supplier performance metrics and schedules

- Industry statistical databases

- Public economic and regulatory information

This comprehensive data ecosystem serves as the foundation for accurate predictions related to cost optimization, procurement strategies, and operational efficiency improvements.

To understand how predictive analytics contributes to the optimization of different manufacturing processes, let’s break down its use cases.

Demand forecasting

Demand in such a dynamic market landscape remains an eternal puzzle – though much depends on what product is being sold, in which market, under what geopolitical conditions, and even… weather conditions.

Consider air conditioning systems as an example. This industry already experiences significant demand spikes and drops depending on the time of year. Now, as the climate warms, demand for such products may increase substantially, and previously marginally profitable markets could become new export destinations.

Even for products with consistent demand, manufacturers can be caught off guard by sudden demand spikes. We witnessed this recently with the medication Ozempic, which gained popularity due to viral social media content. Although it’s a prescription drug for diabetes patients with relatively stable year-round demand, it suddenly began disappearing from pharmacies due to a global trend.

In most cases, sudden demand changes stem from external factors. Take the aforementioned Trump tariffs, which will increase prices of goods exported to the US from the EU or China by at least 20%. This could expose European and Chinese manufacturers to significand demand decreases in their key export destinations and force them to seek alternative markets or reduce production volumes. Conversely, US manufacturers may gain competitive advantages in their domestic market as imported alternatives become more expensive.

How demand forecasting systems protect and empower manufacturers

This is where demand forecasting steps into action. These sophisticated systems provide multi-layered protection and opportunity capture:

1. Early warning systems Advanced algorithms analyze historical patterns, consumer buying habits, market signals, and external factors to identify potential demand shifts weeks or months in advance, allowing manufacturers to adjust production schedules proactively.

2. Surge capacity management When demand spikes are predicted, systems automatically trigger capacity expansion protocols – from scheduling overtime shifts to activating backup suppliers and increasing raw material orders to meet unexpected volume requirements.

3. Revenue optimization By accurately predicting high-demand periods, manufacturers can strategically adjust pricing models and prioritize high-margin products, maximizing revenue potential during peak periods.

4. Overproduction prevention Perhaps most importantly, these systems prevent costly overproduction by identifying declining demand trends early, allowing companies to reduce output before accumulating excess inventory that leads to storage costs and potential losses.

Inventory management

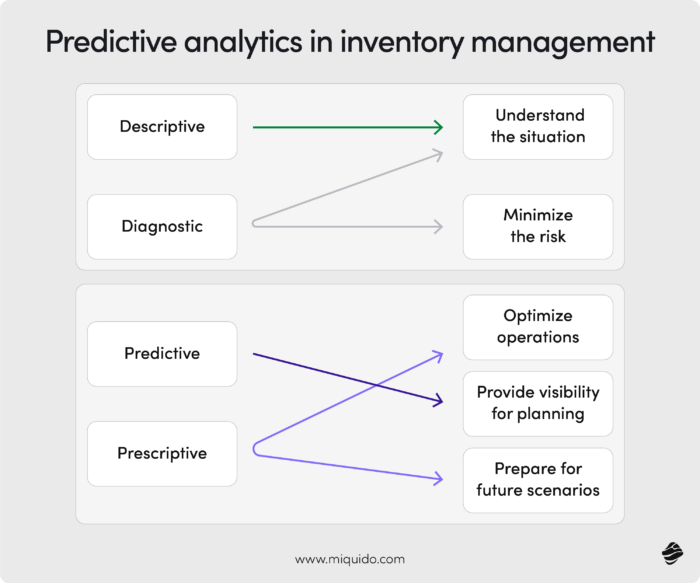

In the case of products with long shelf life, one might think – well, there’s a surplus, but the product can be stored and gradually moved out of inventory. Unfortunately, this still means costs – and significant ones at that. A recent study by IHL Group found that inventory distortion costs retailers nearly $1.77 trillion worldwide. This results from creating surpluses or shortages in storage space, as well as the lack of proactive prevention strategies.

Predictive AI provides these strategies, allowing companies to optimize inventory management and take preemptive actions that prevent surpluses or shortages. For example: based on historical data, the system can identify patterns of declining demand for specific products or models in particular months and suggest adjusting their prices on ecommerce platforms to accelerate sales.

Alternatively, it might detect seasonal trends and recommend temporarily shifting production capacity toward higher-demand product lines, or identify optimal timing for promotional campaigns to clear excess inventory before storage costs accumulate.

Product development strategy optimization

In product development, timing is everything. Predictive analytics solution helps manufacturing businesses stay ahead by identifying shifting customer preferences, anticipating material constraints, and evaluating product success probabilities – before a prototype is even built.

This forward-looking approach enables companies to fine-tune R&D pipelines, reduce time-to-market, and avoid costly design missteps. It’s the difference between chasing trends and setting them.

Predictive maintenance

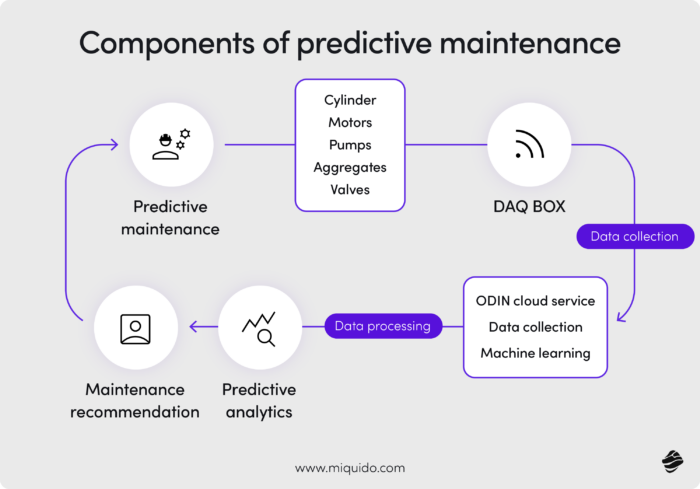

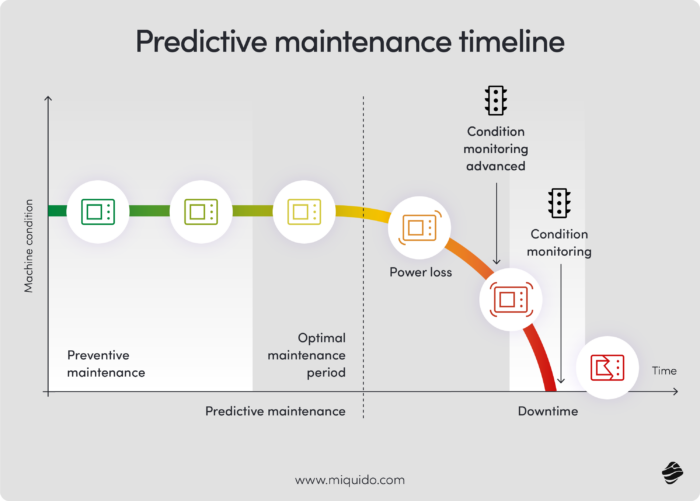

Predictive maintenance analytics uses data from sensors, machines, and operational systems to detect early signs of equipment degradation. Instead of waiting for a failure, AI models predict when a component is likely to fail, enabling repairs or replacements before the equipment downtime occurs.

This method significantly improves the efficiency and reliability of manufacturing operations. According to Deloitte, predictive maintenance can reduce unplanned downtime by up to 30%, while cutting maintenance costs by 20% (source).

Let’s take a closer look at how this works in practice.

Scenario: Label printer failure in a yogurt factory

In a highly automated yogurt plant, every step – fermentation, bottling, sealing, and labeling – is coordinated with precision. The final phase involves a printer adding vital labeling data required for compliance.

What goes wrong:

A malfunctioning label printer fails silently, producing unmarked packages. As expiry dates and batch numbers are legally required for food traceability, the entire batch must be discarded.

The result:

Financial loss, increased emissions, disrupted deliveries, and reputational risk.

How predictive AI could help:

By tracking printer behavior – like ink flow, print accuracy, and system delays – AI would have flagged anomalies in real time, pausing production before costly waste was generated.

Scenario: CNC configuration mismatch in custom window frame production

Custom manufacturing demands perfect alignment between design files and execution machinery. When a joinery firm received an order for specialized window frames, their ERP and CNC systems were expected to communicate flawlessly.

What goes wrong:

A sync error causes outdated design files to be sent to production. Machines perform flawlessly – but on the wrong specifications.

The result:

Hundreds of frames are wasted, deadlines are missed, and client trust erodes.

How predictive AI could help:

An intelligent agent could have validated file versions before execution, flagged discrepancies, and prevented the error entirely.

This use case of predictive maintenance is particularly common among automotive companies. For instance, at BMW’s Regensburg plant, predictive maintenance is already used to monitor conveyor systems. Sensors combined with AI detect fault patterns early based on real time data as well as operation and maintenance history – avoiding unplanned halts and maintaining consistent output across the production line.

The progress of generative AI makes it easier to radically improve operational efficiency of the assembly line and proactively reduce costs of the potential downtimes. Take the example of Siemens Healthineers, which has has developed predictive maintenance solutions that utilize generative AI to enhance the reliability of medical imaging equipment. Generative AI can enhance the future of predictive analytics by synthesizing complex patterns from vast data points to generate more accurate forecasts and proactive decision-making strategies.

Energy optimization

Energy costs are no longer a fixed overhead – they’re a fluctuating risk. Predictive analytics helps manufacturers optimize usage by forecasting demand, integrating real-time consumption data, and adjusting operations dynamically.

By aligning production schedules with energy availability and pricing trends, companies can lower costs and reduce their environmental footprint. A good example of how a manufacturer benefiting from energy optimization is Bosch, who implemented AI-based energy management systems in its manufacturing plants.

Their systems predict energy consumption on production lines with the help of advanced analytics, enabling continuous production scheduling and incorporating business and environmental factors, such as customer demand forecasts and weather conditions. This approach has led to energy savings and reduced emissions.

Supply chain management

Today’s supply chains are intricate, global, and vulnerable to sudden shocks. Predictive analytics in supply chain operations management allows manufacturers to simulate disruptions, monitor transport bottlenecks, and anticipate inventory shortages before they cascade into full-blown crises.

Nowhere is this clearer than in the pharmaceutical industry, where delays can become matters of life and death.

Scenario: Supply chain breakdown for a critical drug due to sea route blockage

A life-saving antibiotic depends on a single ingredient shipped through the Suez Canal. When the canal becomes blocked, API shipments are delayed by weeks.

The result:

Production halts, hospitals face shortages, and contractual penalties mount. The public health risk escalates rapidly.

How predictive AI could help:

With real-time monitoring of maritime traffic and outbreak-driven demand forecasting, AI could have prompted early action – rerouting cargo or increasing buffer stock before the crisis peaked.

Workforce management

AI-enhanced workforce planning uses predictive models to optimize staffing levels, skill deployment, and shift scheduling. This ensures that manufacturing operations remain agile, responsive, and adequately staffed –even when labor markets are volatile or demand spikes unexpectedly.

Analyzing the number of errors, delays and other data from the assembly line, machine learning algorithms can draw valuable insights on employee productivity. This way, the manufacturers are capable of stepping in with measures like collective training, preventing the drop in customer satisfaction or quality issues.

Predictive analytics can also flag potential skill gaps, helping HR teams develop training roadmaps aligned with upcoming technology shifts or equipment upgrades.

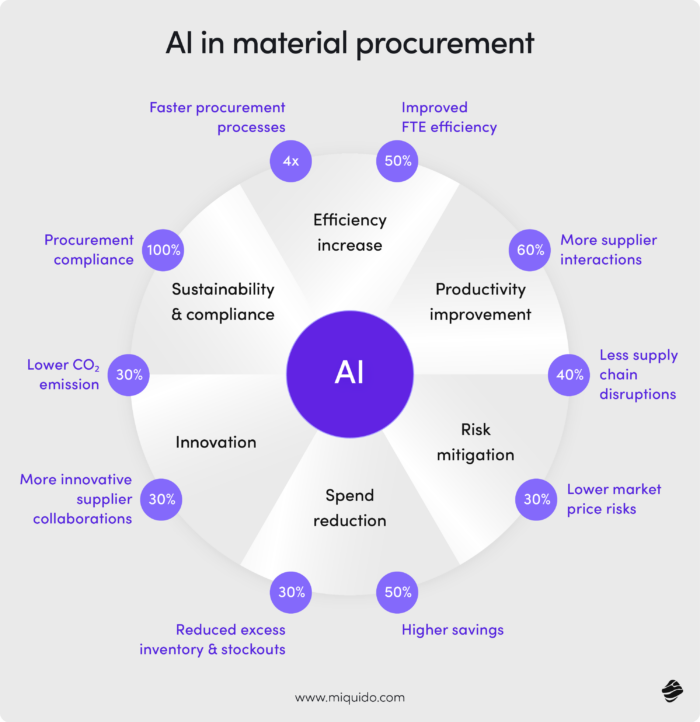

Material procurement

Raw materials are the lifeblood of manufacturing processes – but sourcing them reliably and sustainably is becoming harder. Predictive analytics enables procurement teams to anticipate price fluctuations in raw material costs, track supplier risk, and plan smarter replenishment strategies.

Scenario: Closure of the last domestic wool washing facility due to regulatory pressure

A UK-based luxury fashion brand loses its only domestic wool scouring partner due to new environmental regulations. The company faces a dilemma: either delay production or shift to overseas processing, undermining its sustainability claims.

The result:

Missed seasonal sales, higher logistics costs, and reputational strain.

How predictive AI could help:

By monitoring regulatory trends and vendor risk factors, AI could have signaled the looming shutdown – allowing for contingency plans such as early stockpiling or vetting alternative partners ahead of time.

Bring your manufacturing operations to the next level with advanced data analytics

In many regions, the manufacturing industry is currently struggling to maintain profitability, and increasingly strict regulations aren’t helping in the fight for efficiency and competitiveness. Predictive analytics brings an opportunity to gain competitive advantage, and data-driven decisions are the best weapon in the pursuit of better future outcomes for your facility.

Our experience will help you seamlessly integrate enterprise systems with modern AI-based solutions and move from manual data collection and traditional statistical models to automated insights and systems that continuously learn and improve their accuracy. Benefit from our efficient frameworks like AI Kickstarter and implement GenAi in manufacturing at the fraction of time and costs.

![[header] predictive analytics in manufacturing cut downtime & costs](https://www.miquido.com/wp-content/uploads/2025/06/header-predictive-analytics-in-manufacturing_-cut-downtime-costs.jpg)

![[header] top 10 generative ai use cases in manufacturing](https://www.miquido.com/wp-content/uploads/2025/07/header-top-10-generative-ai-use-cases-in-manufacturing-432x288.jpg)

![[header] computer vision in manufacturing how to maximize its effectiveness with genai](https://www.miquido.com/wp-content/uploads/2025/07/header-computer-vision-in-manufacturing_-how-to-maximize-its-effectiveness-with-genai-432x288.jpg)

![[header] ai for manufacturing compliance](https://www.miquido.com/wp-content/uploads/2025/07/header-ai-for-manufacturing-compliance-432x288.jpg)