It's 1995, and a production manager rushes between workstations clutching a stack of paper reports, frantically trying to coordinate between the shop floor and corporate systems. Quality issues surface hours after defective products roll off the line.

Fast-forward to 2025, and these challenges no longer viable. AI algorithms can seamlessly orchestrate the entire manufacturing symphony - predicting equipment failures before they happen, adjusting production schedules in real-time as demand shifts, and optimizing inventory levels with surgical precision. The modern factory floor doesn't just respond to problems; it prevents them across the modern manufacturing processes.

That's how a regular day can look like on the factory floor coordinated by the AI-driven manufacturing execution software. And although it is not yet a golden standard across all manufacturing niches, those who decide to supercharge their systems with artificial intelligence rarely regret it.

The research from Accenture reveals that three-in-four (74%) organizations have seen investments in generative AI and automation meet or exceed expectations, with 63% planning to increase their efforts and further strengthen these capabilities by 2026.

There is no transition to Industry 4.0 without AI-backed Manufacturing Execution Systems (MES). In this article, we outline their use cases and explore how to maximize their efficency.

What is MES?

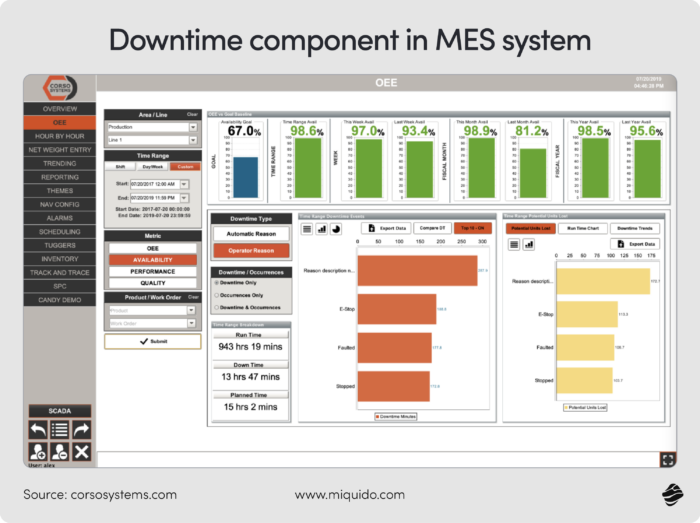

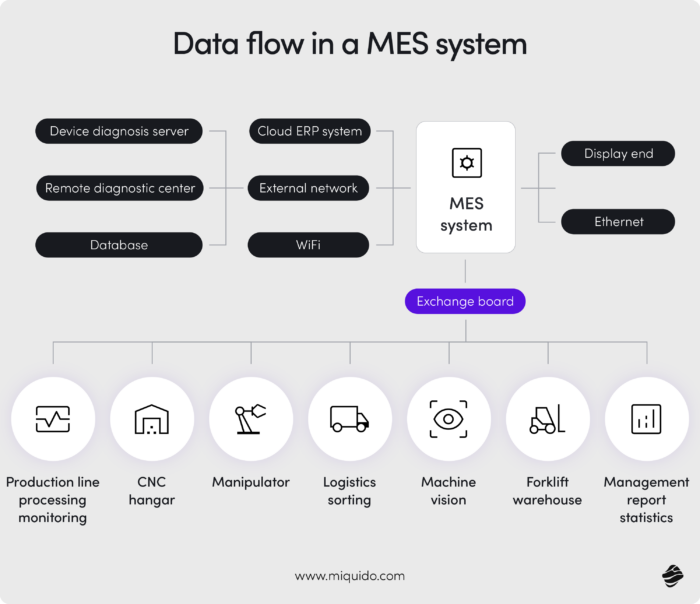

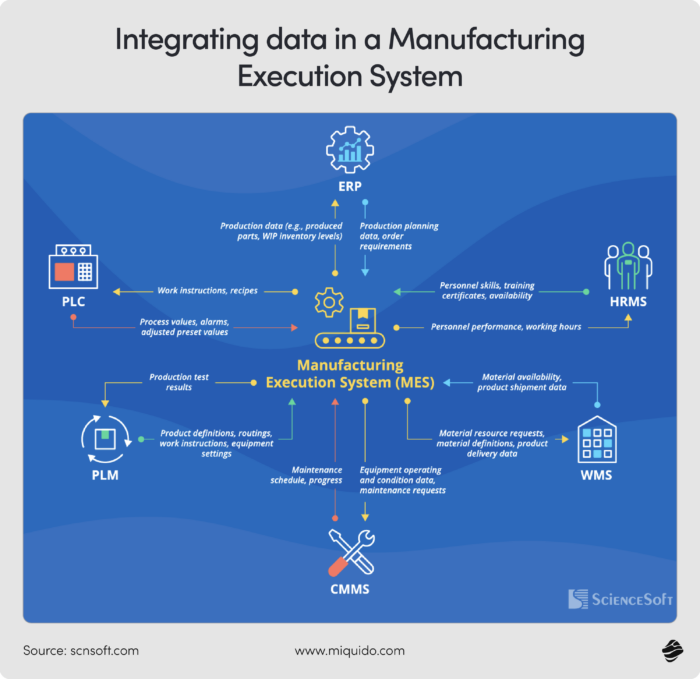

At its core, MES is the digital nervous system that monitors, tracks, documents, and controls manufacturing processes from raw materials to finished goods. It bridges the gap between enterprise systems (ERP) and shop floor control systems (PLC/SCADA), creating seamless information flow across operations.

Traditional MES systems vs. AI-driven MES systems

Without AI integration, traditional manufacturing execution systems operate through predefined rules and manual inputs, requiring operators to constantly monitor dashboards and make decisions based on historical data rather than predictive insights. These conventional systems struggle with dynamic manufacturing environments, often missing critical patterns in equipment behavior that could signal impending failures.

Manual quality control processes become bottlenecks, as human inspectors cannot match the speed and consistency required for high-volume production lines. The result is increased downtime, machine failures, higher maintenance costs, quality inconsistencies, and suboptimal resource allocation that directly impacts overall manufacturing efficiency.

From factory controller to digital conductor: How MES transforms in Industry 4.0

Remember our factory manager buried under paper schedules? His traditional MES was like a reliable traffic cop, directing information flow between enterprise systems and shop floor with predetermined rules. But when Industry 4.0 arrived, everything changed.

The traditional MES was like a librarian – excellent at cataloging information when asked. The Industry 4.0 MES, on the other hand, is like a detective combined with a master strategist, able to analyze production data, predict outcomes, and orchestrate responses before problems surface. It’s a shift from passive systems to active intelligence, enabling manufacturers to respond dynamically to change.

This new, augmented MES must be service-oriented and adaptable. It seamlessly processes IoT streams, integrates with AR tools to guide technicians, and supports real time monitoring across mobile and cloud platforms. Most remarkably, it facilitates communication between autonomous equipment, pushing the boundaries of continuous improvement through hyper-connected environments.

If Industry 4.0 is a symphony, MES is both conductor and concert hall. It unites IoT sensors, mobile computing, cloud storage, big data analytics, machine learning, robotics, and AR/VR into one harmonious performance. When machine learning predicts a quality issue, IoT sensors can adjust parameters in real time, mobile apps notify staff, and cloud systems revise production schedules – all in synchronized automation.

How can MES benefit from AI-driven automation?

When you enrich the traditional MES with AI, it reveals its superpowers. Consider inventory management alone: A Gartner study found that companies using AI-driven MES solutions experienced a 10-15% improvement in inventory turnover, as AI helped optimize production planning and reduced overproduction and excess inventory.

AI-powered MES systems employ sophisticated algorithms to transform traditional manufacturing operations into intelligent, self-optimizing environments. Machine learning models excel at pattern recognition in equipment data, while predictive analytics in manufacturing can forecast maintenance needs with remarkable accuracy. Computer vision systems, meanwhile, revolutionize quality control by detecting defects that human inspectors might miss.

Each AI component serves a specific purpose to optimize manufacturing processes and enhance operational efficiency. Neural networks handle complex equipment sensor data to predict failures before they occur, dramatically reducing unplanned downtime. Optimization algorithms analyze production workflows to identify bottlenecks and recommend process improvements that boost throughput while minimizing waste.

Whether you implement existing AI-enhanced MES solutions or invest in custom development for specialized manufacturing needs, your system will likely integrate multiple AI technologies. Increasingly combined with natural language processing and data integration capabilities, these systems can interpret data from various sources, translating complex manufacturing metrics into actionable insights.

AI in MES: use cases

The smart factory can apply AI in manufacturing execution systems for various different purposes, taking advantage of historical and real time data for process optimization.

Smart scheduling: Master chess player

AI-driven MES systems transform traditional scheduling from rigid spreadsheets into dynamic orchestration, where algorithms continuously reschedule operations based on real-time machine availability and material flow. Due to AI capabilities, it can predict machine failures and optimize resource allocation across multiple production lines. This intelligent approach to manufacturing processes boosts production efficiency by eliminating bottlenecks before they form, ensuring every resource moves in perfect harmony.

Anomaly detection: Early warning system

Unsupervised learning models embedded in AI systems act like digital sentinels, detecting subtle deviations from normal operations long before human eyes would catch them. These predictive analytics capabilities enable MES systems to flag potential issues and trigger corrective actions, dramatically improving operational efficiency by preventing costly breakdowns and quality failures.

Supply chain integration: Crystal ball effect

AI-driven MES platforms seamlessly integrate predictive AI models with supply chain data, transforming reactive production planning into proactive strategic positioning. This successful implementation of AI in production planning and enterprise resource planning integration allows manufacturing processes to adjust automatically when suppliers signal delays or material shortages, maintaining smooth operations despite external disruptions.

Digital twins: Parallel universe factory

AI-powered digital replicas create virtual manufacturing environments where MES systems can test countless scenarios without risking real production. These sophisticated AI systems simulate everything from equipment failures to demand spikes, enabling operational efficiency improvements through risk-free experimentation and optimization of manufacturing processes.

Augmented reality: The intelligent guidance system

AR technology transforms MES systems into intelligent guides that overlay real-time production data directly onto the physical workspace, empowering operators with instant access to critical information. This seamless integration of digital intelligence with physical manufacturing processes accelerates decision-making and reduces errors, proving that successful implementation of AI-driven MES extends far beyond traditional screens and dashboards.

AI in manufacturing execution systems: Industry scenarios

To understand the potential of AI driven MES systems, let's take a closer look at industries with the biggest demand for such automation due to supply chain complexity, quality control requirements, or regulatory challenges and sustainability goals.

AI in pharma manufacturing execution systems

AI-powered execution systems have transformed pharma environment into a precision-driven ecosystem where every decision is informed and every result is predictable. The outcomes of this transition will be significant: McKinsey's analysis reveals that generative AI could impact the pharmaceutical manufacturing industry by 2.6 to 4.5 percent of annual revenues – $60 billion to $110 billion annually.

AI execution systems analyze logs and batch reports through natural language processing, detecting early deviation signs before they cascade. Adaptive process control adjusts critical parameters in real-time, ensuring consistent product quality - precision that literally saves lives.

Another crucial area in pharma, which AI streamlines, is the regulatury compliance. AI-driven execution systems ensure GMP adherence by flagging anomalies and maintaining comprehensive audit trails automatically, transforming data collection from frantic scrambles into confident compliance presentations.

When predictive maintenance prevents equipment failures and intelligent batch record automation eliminates human error, pharmaceutical companies don't just achieve compliance, but they redefine manufacturing precision.

AI in automotive Manufacturing Execution Systems

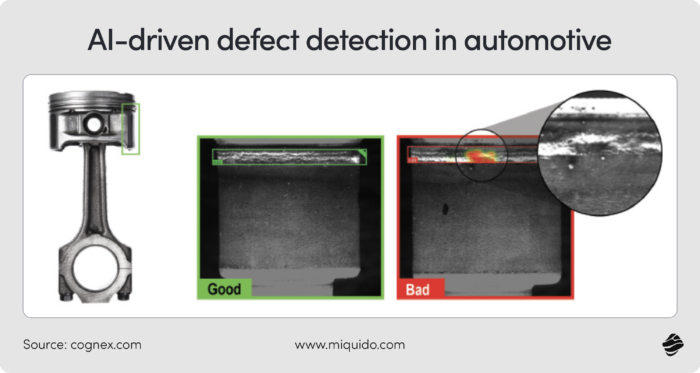

For the automotive industry, intelligent engineering optimization is the main area where AI in MES systems has a revolutionary potential. McKinsey's statistics demonstrate that AI adoption in product design has achieved a 50% reduction in design time and a 40% increase in product quality.

This transforms complex product development cycles into streamlined innovation pipelines. Computer vision systems detect surface defects and assembly issues in real-time, while artificial intelligence optimizes multi-robot workflows and adapts to changes instantaneously.

In the automotive industry, precision manufacturing demands adaptive intelligence. AI-driven execution systems support variant-rich production lines with dynamic configuration and sequencing. This enables customization at unprecedented scale.

AI in foodtech Manufacturing Execution Systems

The adaptation to the industry's most critical challenges while delivering measurable improvements in quality, efficiency, and regulatory compliance is the main reason why foodtech companies get interested with AI.

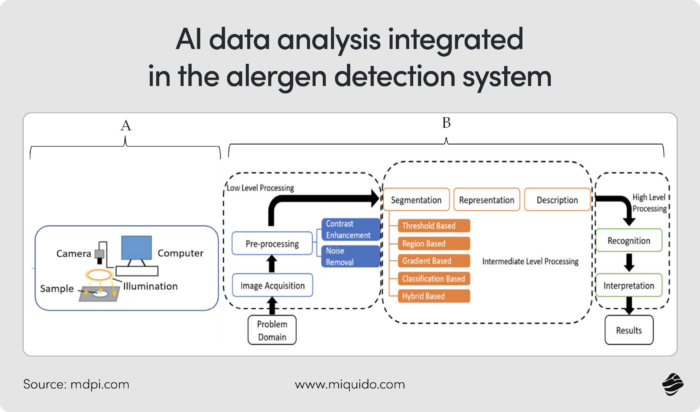

AI revolutionizes food safety through intelligent shelf-life management. Advanced artificial intelligence models analyze real-time environmental data to forecast spoilage patterns and suggest optimal stock rotation strategies.

This turns inventory management from reactive scrambles into proactive precision operations. Machine learning algorithms discover optimal combinations of ingredients for taste, nutrition, and cost efficiency. This transforms recipe development into data-driven culinary science.

At the same time, AI-driven execution systems can ensure contamination prevention through intelligent allergen detection. They use advanced image and sensor analysis to eliminate cross-contamination risks automatically.

AI in woodworking Manufacturing Execution Systems

AI-powered execution systems have revolutionized woodworking manufacturing into a resource-optimized ecosystem where every material decision maximizes value and every production outcome eliminates waste. This intelligent transformation addresses the industry's sustainability challenges while delivering unprecedented efficiency in custom manufacturing operations.

Advanced algorithms can, for instance, identify optimal cutting patterns to maximize material utilization. Predictive models estimate tool wear and schedule timely replacements. This turns maintenance from reactive repairs into proactive precision operations. AI adapts workflows for mass customization of cabinetry, furniture, and panels, transforming bespoke manufacturing into scalable operations.

In the woodworking industry, material efficiency represents both environmental responsibility and economic opportunity. AI-driven execution systems analyze production waste and identify improvement areas in material use and process steps automatically, transforming resource consumption from wasteful practices into optimized sustainability.

Overcome MES systems implementation challenges with our tailored approach

Bringing AI into manufacturing means more than adding new tools – it requires solving challenges like outdated infrastructure, fragmented data, and internal resistance. Old infrastructure often calls for middleware and phased rollouts. Data silos? They need unified architectures and robust integration platforms. And when it comes to getting people on board, targeted training and hands-on pilot programs make all the difference.

That’s why your approach to technical integration can’t be the same as your strategy for managing change or staying compliant. Each challenge demands a different playbook. If you're looking into AI for manufacturing, you're probably aiming to boost performance without delays, compliance headaches, or budget overruns. But a solid software partner brings more to the table than just clean code.

Between evolving regulations, complex system demands, and organizational pushback, most manufacturers face similar hurdles. What sets successful implementations apart is having the right expertise.

With deep industry know-how, manufacturing software development experience, and a focus on MES integration, we help factories unlock AI’s full potential – with less guesswork and more results.

![[header] ai in manufacturing execution systems – use cases](https://www.miquido.com/wp-content/uploads/2025/06/header-ai-in-manufacturing-execution-systems-–-use-cases.jpg)

![[header] top ai fintech companies transforming finance in 2025](https://www.miquido.com/wp-content/uploads/2025/05/header-top-ai-fintech-companies-transforming-finance-in-2025-432x288.jpg)

![[header] top 9 cybersecurity solutions for the manufacturing industry (1)](https://www.miquido.com/wp-content/uploads/2025/12/header-top-9-cybersecurity-solutions-for-the-manufacturing-industry-1-432x288.jpg)